Finishing and Repairing Work

966582322566

Painting and Coating

Flooring

Plastering and Drywall

Masonry

Electrical and Plumbing

case study

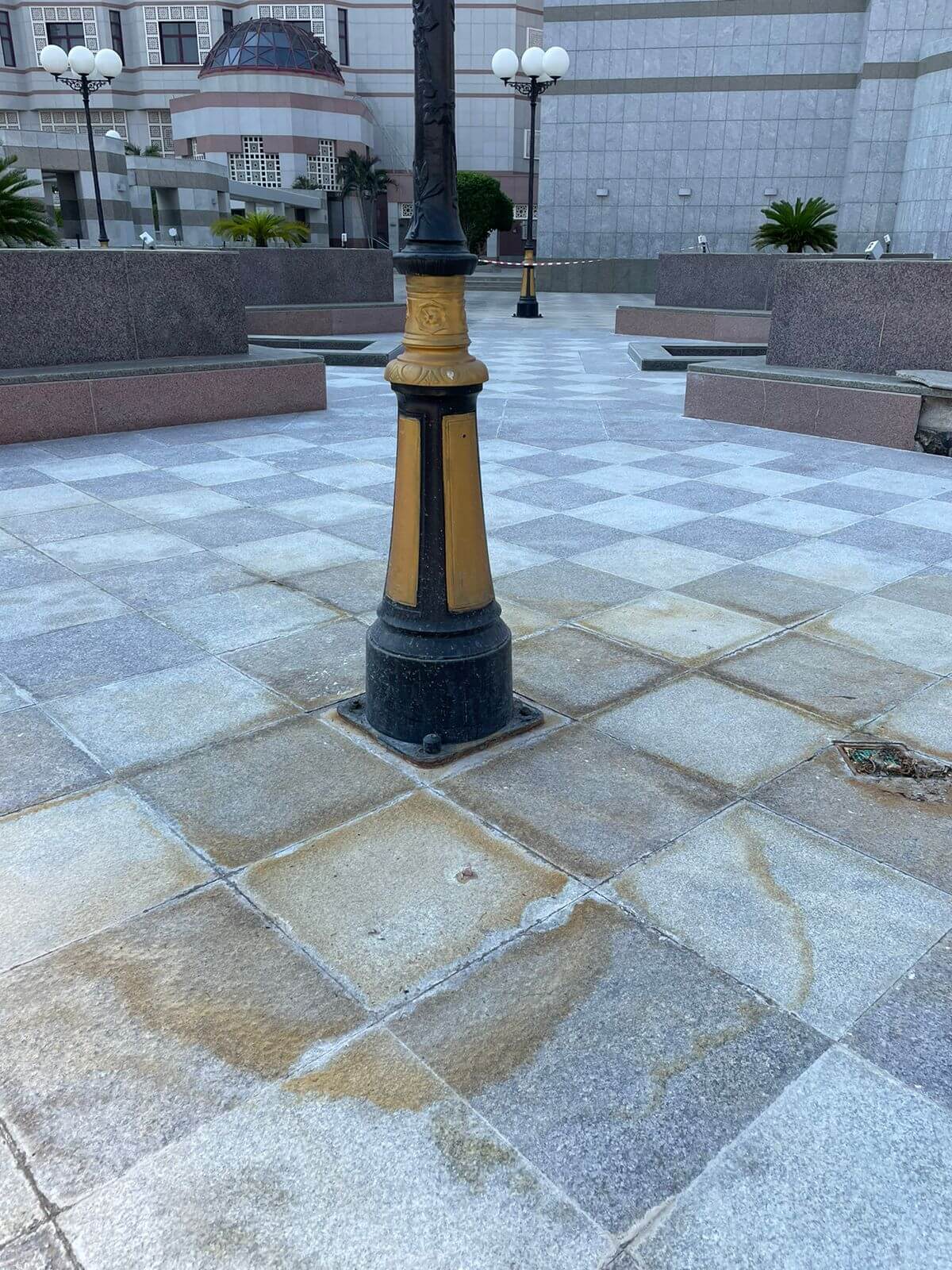

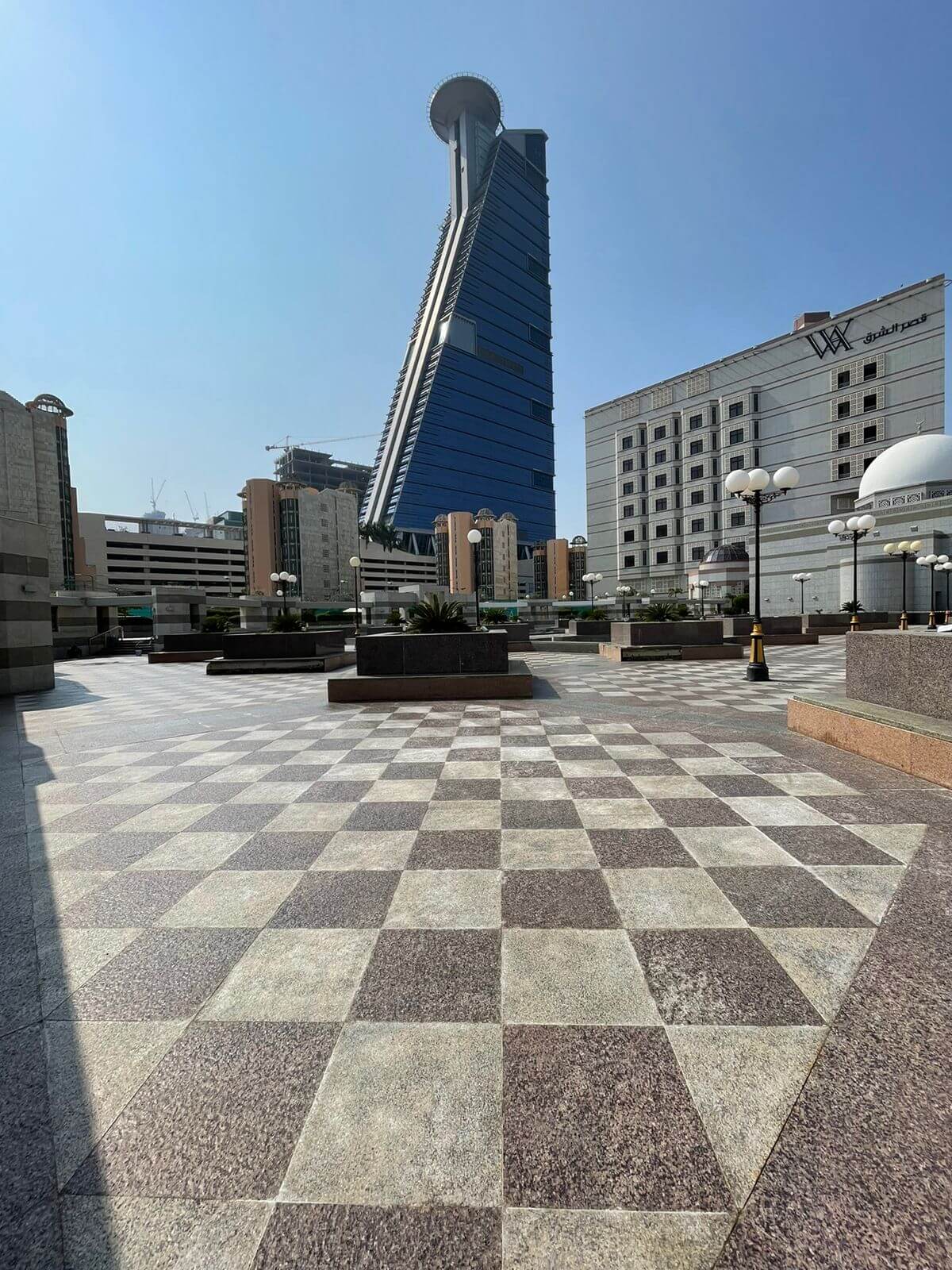

Granite Polishing and Restoration for HILTON

Challenge:

On initial inspection of the site, the granite surfaces were found to be extensively rusted, requiring a comprehensive approach to not only restore but also enhance their durability and appearance.

Situation Analysis

The state of the granite presented a unique challenge. The rust and deterioration had affected the aesthetics and integrity of the surfaces. Our team was tasked with not only repairing the granite but also ensuring its long-term preservation and ease of maintenance.

Action Taken

Sample Demonstration: Before commencing the project, we created a sample section to demonstrate the potential outcome and to set the expectations for the quality of work.

Granite Surface Preparation:Grinding: We began by grinding the edges, corners, and joints of the granite. This process was crucial for smoothing out uneven surfaces and preparing the granite for further treatment.

Chemical Washing: Post-grinding, the surfaces were washed with a specific chemical solution. This step was essential for removing any residual dirt, rust, and debris.

Cleaning with Soft Cloth and Steel Brush: After the chemical wash, a soft cloth was used for gentle cleaning, followed by a steel brush to meticulously remove all dust and fine particles, ensuring a perfectly clean surface for the final treatment.

Application of Bellinzoni HP:We concluded the restoration process by applying Bellinzoni HP, a high-quality final coat specially designed for granite surfaces. This product not only enhances the aesthetic appeal of the granite but also provides a water-repellent layer, making it easier to clean and maintain in the future.

Results

The entire project, covering an area of 1000 square meters, was completed within an impressive timeframe of 5 days. The restoration not only returned the granite to its original luster but also provided additional protection against future wear and tear.

Conclusion

This granite polishing and restoration project showcased our ability to handle large-scale surface treatment tasks efficiently and effectively. Our meticulous approach, from initial grinding to the final application of a protective coat, ensured a high-quality finish. The successful completion of this project within a tight deadline highlights our commitment to delivering exceptional results, even in challenging situations.

This case study stands as a testament to our expertise in surface restoration and our dedication to enhancing the longevity and beauty of architectural materials. Our team’s proficiency in employing advanced techniques and high-quality materials like Bellinzoni HP ensures that our restoration work not only repairs but significantly improves the overall quality and resilience of the treated surfaces.

By transforming a challenging situation with rusted and deteriorated granite into a beautifully polished and protected area, we have demonstrated our commitment to excellence and customer satisfaction. This project underscores our capability to deliver superior surface treatment solutions, further establishing our reputation as a leader in the field of architectural restoration and maintenance.

Precast Concrete Column Repair for Hilton Swimming Pool Area

Challenge:

Upon initial inspection, the precast concrete columns and beams showed visible cracks and corner damages, requiring an extensive repair process to ensure structural integrity and aesthetic appeal.

Situation Analysis

The site’s condition presented a significant challenge, with deteriorating concrete and corroded steel reinforcements. A total of 120 columns and beams needed urgent attention to prevent further degradation and to maintain safety standards.

Action Taken

Initial Preparation: Ripping of Cracks and Loose Concrete: The first step involved removing all loose concrete and opening up the cracks to prepare for the repair work. This process was essential to ensure a solid foundation for the subsequent restoration steps.

Steel Grinding and Treatment: Grinding of Rusted Steels: All exposed steel bars, affected by zinc rust, were thoroughly ground to remove rust and any deteriorated layers, preparing them for further treatment.

Application of Zinc-Rich Repairing Material: After grinding, a zinc-rich repairing material was applied to the steel bars. This step was crucial for protecting the steel from further corrosion and enhancing the overall strength of the structure.

Concrete Repair and Sealing Crack Closure and Column Repairing: Special concrete grouting material solutions were used to close all cracks and repair the columns. This material was selected for its superior bonding strength and durability.

Application of Primer: A primer coat was applied to the repaired areas, setting the stage for the final protective layer.

Final Coating:

Spray Painting: The final step involved applying a high-quality spray paint, providing a fresh and uniform look while adding an additional layer of protection to the concrete surfaces.

Contact Us

Address

Gharnath Street , opposite Saudi Aramco complex , mushrifa Jeddah KSA

info@dioufalsharq.com

Phone

966582322566